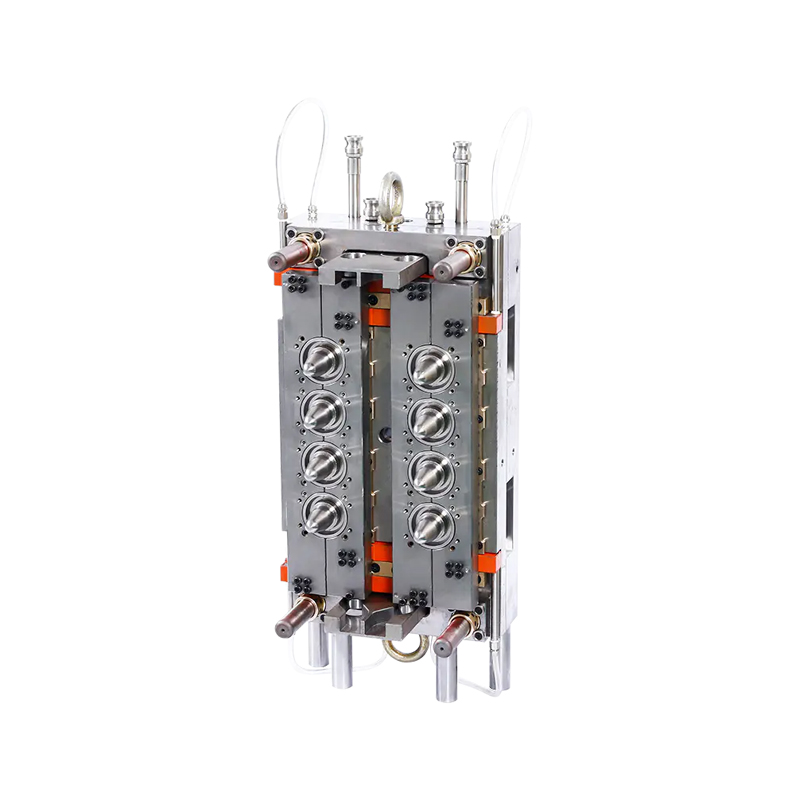

The 8 Cavity Wide-mouth Preform Mold is designed for the efficient production of high-quality preforms that are used in the manufacturing of wide-mouth PET bottles. Featuring eight cavities, this mold allows for the simultaneous production of multiple preforms, increasing production efficiency and reducing manufacturing time. Constructed from durable stainless steel, the mold is ideal for creating preforms that are utilized in a variety of industries requiring strong, reliable, and precisely molded bottles. This mold is an excellent solution for companies looking to enhance their production capacity while ensuring consistent quality in every preform.

Product Advantages

Enhanced Production Efficiency

The 8 cavity mold allows for the production of up to eight preforms in one cycle. This significantly boosts production capacity and reduces cycle time, allowing manufacturers to meet higher demand more effectively. By producing multiple preforms in each injection cycle, businesses can increase output without investing in additional machinery.

Consistency and Precision

Each cavity of the mold is engineered to provide consistent and uniform preforms. The precision design ensures that all preforms meet the required specifications for shape, size, and wall thickness. This consistency is crucial for ensuring that the final wide-mouth bottles perform optimally during the blow molding process and meet quality standards.

Durable and Long-Lasting Construction

Made from high-quality stainless steel, the mold offers exceptional durability and resistance to wear and tear. Stainless steel's strength and corrosion resistance ensure that the mold can withstand the rigors of continuous production in demanding environments. This durable construction also reduces maintenance needs and increases the mold's lifespan.

Cost-Effective Production

The 8 cavity mold provides a cost-effective solution for manufacturers by optimizing the production process. With multiple preforms produced per cycle, businesses can reduce energy consumption and operational costs. The mold's efficiency allows companies to achieve high-volume production without the need for substantial capital investment.

Product Features

Precision Engineering

The mold is crafted with precise tolerances to ensure the uniformity of each preform. The design guarantees that every preform produced is consistent in terms of size, shape, and wall thickness. This level of precision is essential for maintaining high-quality standards throughout the production process.

Stainless Steel Durability

The use of stainless steel in the mold's construction ensures that it can handle the heat and pressure of repeated injection molding cycles without degrading. The material is resistant to rust, corrosion, and wear, making it a long-term investment for manufacturers who require high performance and minimal downtime.

Optimized Cooling System

The mold incorporates an optimized cooling system that helps reduce the overall cycle time. Faster cooling allows for quicker production turnaround, ensuring that preforms are produced efficiently without sacrificing quality. This efficient cooling system also contributes to energy savings by reducing the amount of time required for cooling.

Versatile Design

The 8 cavity mold is designed to work with a variety of injection molding machines, providing flexibility for different production setups. This versatility makes it suitable for companies with diverse manufacturing processes or those looking to integrate the mold into their existing systems without significant adjustments.

Easy Maintenance

The design of the mold ensures that maintenance and cleaning procedures are straightforward and quick. Easy disassembly and reassembly reduce downtime during maintenance, allowing production to resume promptly. Regular maintenance is made easier due to the mold's durable stainless steel construction, which requires less frequent repairs.

Product Applications

Food and Beverage Packaging

The 8 cavity mold is primarily used for producing preforms for wide-mouth PET bottles in the food and beverage industry. These bottles are commonly used for packaging products such as juices, sauces, jams, pickles, and other food items that require easy access for pouring or dispensing. The wide-mouth design ensures convenience and practicality for consumers while maintaining the integrity of the product.

Cosmetic and Personal Care Packaging

The mold is also widely used in the cosmetic industry for producing preforms for packaging personal care products. This includes products like lotions, shampoos, conditioners, and other cosmetic items that are typically packaged in wide-mouth containers. The high-quality preforms produced by the mold ensure that the bottles meet both the functional and aesthetic needs of the cosmetic packaging market.

Pharmaceutical and Health Products

Wide-mouth PET bottles are commonly used in the pharmaceutical industry for packaging health-related products such as vitamins, supplements, and liquid medicines. The 8 cavity mold ensures that the preforms meet the required safety and quality standards, providing secure packaging that protects the integrity of the products.

英语

英语 法语

法语