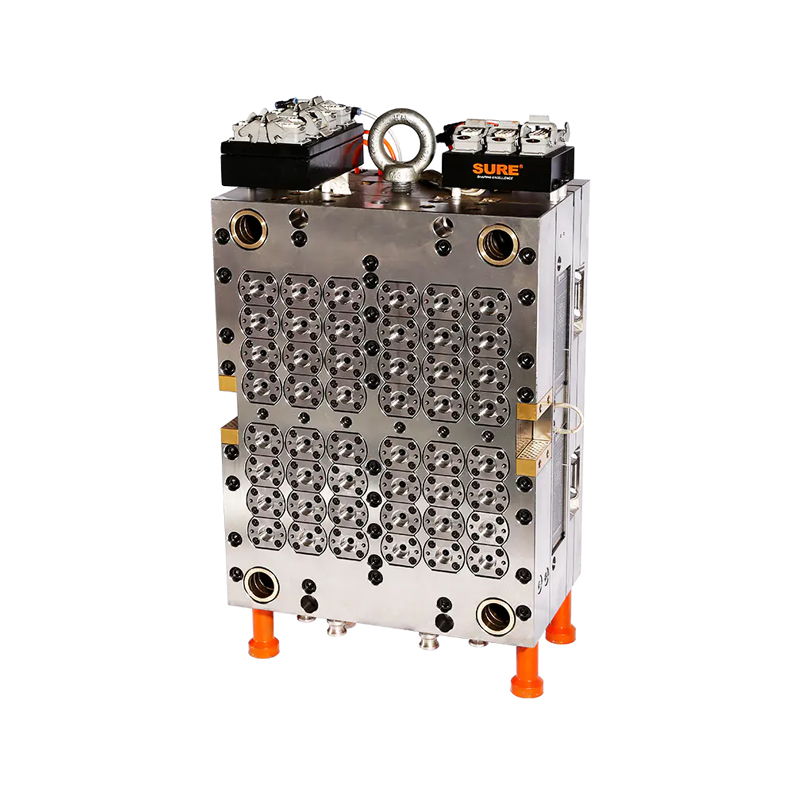

The 48 Cavity Precision Blood Collection Tube Mold is an advanced tool designed for the efficient and precise manufacturing of blood collection tubes. This mold is designed to meet high standards in medical and laboratory environments where accuracy, consistency, and durability are crucial. It is an essential product for those who require precise molding for the production of blood collection tubes used in diagnostic and clinical procedures.

Product Advantages

Precision Molding:

The mold is engineered with exact specifications to ensure that each blood collection tube produced is uniform in size and shape. This minimizes inconsistencies and enhances the quality control process.

Durability and Longevity: Made from high-quality materials, the mold is designed to withstand the repeated stresses of molding processes. Its durability ensures a long service life, reducing the frequency of replacement and maintenance.

Cost-Effectiveness:

By producing 48 cavity in one cycle, this mold significantly increases production capacity, reducing overall manufacturing costs. This makes it an ideal solution for the mass production of blood collection tubes.

Ease of Use: The mold's user-friendly design allows for seamless integration into existing production lines. It is simple to operate, requiring minimal training for personnel.

Product Features

48 Cavity Design:

This mold has the capacity to create 48 blood collection tubes in a single molding cycle. This high-efficiency design significantly boosts production throughput while maintaining the integrity of each tube.

Precise Mold Construction: The design ensures that each cavity is perfectly aligned, providing uniformity and reducing variations in tube size, which is essential for compatibility with automated machinery in laboratories and healthcare settings.

Material Compatibility:

The mold is compatible with a wide range of medical-grade plastics, ensuring flexibility in the choice of material for the tubes. This allows manufacturers to meet specific regulatory requirements and customer preferences.

Advanced Cooling System:

An integrated cooling system ensures that the blood collection tubes solidify quickly, improving cycle times without compromising the quality of the molded product.

Corrosion-Resistant:

The mold is made of materials that are resistant to corrosion, ensuring that it remains functional and reliable throughout its lifespan, even with frequent exposure to the chemicals and substances used in the blood collection tube manufacturing process.

Product Uses

Mass Production of Blood Collection Tubes:

The primary use of this mold is in the mass production of blood collection tubes for medical and laboratory purposes. It is suitable for large-scale manufacturing where high precision and speed are essential.

Quality Control in Medical Equipment Manufacturing:

By ensuring uniformity and consistency in the production of blood collection tubes, this mold helps manufacturers maintain high standards for quality control in the healthcare industry.

Customization for Specific Tube Designs:

Manufacturers can use this mold to produce tubes with specific features or dimensions, catering to diverse customer needs in various clinical settings.

Research and Development:

The mold is also used in research and development for the creation of prototype blood collection tubes or for testing new materials, ensuring that they meet industry standards for safety and functionality.

The 48 Cavity Precision Blood Collection Tube Mold is an essential tool for efficient, high-quality production of blood collection tubes. Its precision design, durable construction, and high-capacity mold help manufacturers meet the increasing demand for medical-grade tubes while maintaining quality and minimizing costs. With features such as material compatibility, corrosion resistance, and an advanced cooling system, this mold is built to withstand the challenges of large-scale production. Its use extends to various applications in medical equipment manufacturing, research, and development, making it a versatile and reliable solution for the healthcare industry.

英语

英语 法语

法语