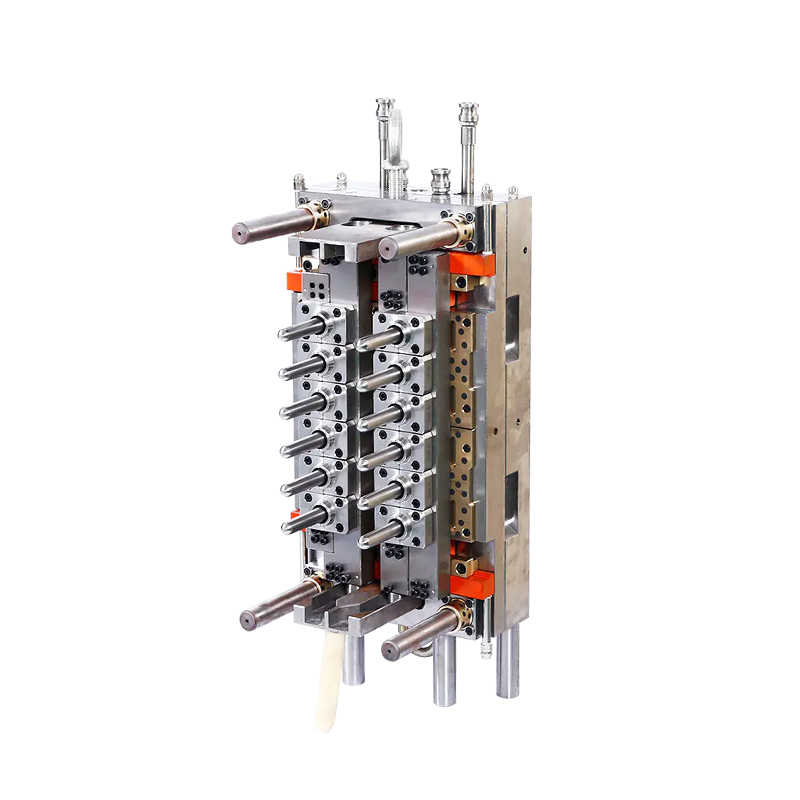

This mold features twelve cavity that can simultaneously produce preforms, allowing for enhanced production capacity while maintaining precision. Suitable for a wide range of applications, the semi-automatic mold is ideal for businesses that seek a balance between manual and fully automated production systems. It is particularly useful for manufacturers of PET bottles in industries such as food and beverage, cosmetics, pharmaceuticals, and more.

Product Advantages

Increased Production Efficiency

The 12 cavity mold design allows for the simultaneous production of twelve preforms in a single injection cycle. This significantly increases production efficiency by enabling manufacturers to produce a higher volume of preforms within a shorter period. This feature is beneficial for companies that need to meet high demand with consistent output.

Semi-Automatic Operation Flexibility

The semi-automatic nature of the mold provides a practical solution for businesses that may not have the capacity for full automation. This mold allows manufacturers to manually control certain aspects of the production process while still benefiting from the efficiency and precision of semi-automatic systems. The flexibility makes it ideal for businesses looking for a cost-effective solution without fully automated systems.

Consistent Quality

With twelve cavities producing preforms at the same time, the mold ensures consistent quality across each preform. This uniformity reduces production defects and ensures that each preform meets the same high standards. Consistency in preforms is crucial to achieving high-quality final products in the blow molding process.

Reduced Operational Costs

By producing multiple preforms per cycle, the mold helps optimize production time, ultimately reducing operational costs. The increased efficiency translates to lower energy consumption per unit of output, making it a more cost-effective choice for manufacturers aiming to maintain quality while controlling costs.

Product Features

Precision Design and Engineering

The 12 cavity mold is meticulously designed to provide high precision in the production of PET preforms. Each cavity is crafted to ensure that preforms are produced with uniform dimensions, wall thickness, and overall quality. The precision ensures the consistency necessary for successful blow molding and subsequent filling processes.

Durable Construction

Constructed from premium-grade steel, the mold is designed for durability and longevity. It is built to withstand the pressures of continuous use in high-volume manufacturing environments. The robust materials ensure that the mold maintains its performance over time, leading to lower maintenance and replacement costs.

Optimized Cooling System

The mold incorporates an efficient cooling system, designed to reduce cycle times. This optimized cooling process allows preforms to solidify faster, contributing to quicker turnaround times for each production cycle. The reduction in cooling time also minimizes energy consumption, making the mold more energy-efficient.

Easy to Maintain and Clean

The design of the mold allows for easy cleaning and maintenance. Quick disassembly and straightforward cleaning procedures reduce downtime and ensure that the mold remains in optimal condition throughout its service life. This ease of maintenance contributes to overall productivity by minimizing interruptions in the production process.

Versatility and Compatibility

The 12 cavity mold is compatible with a range of injection molding machines, making it a versatile option for various production setups. Manufacturers can integrate the mold into their existing systems with minimal adjustments, reducing the need for significant equipment upgrades or changes.

Product Applications

Food and Beverage Packaging

The 12 cavity mold is widely used in the production of PET preforms for food and beverage packaging. Whether for carbonated drinks, bottled water, or other beverages, the mold produces preforms that are strong, durable, and capable of withstanding the demands of beverage bottling. It ensures that the preforms meet food safety standards and are suitable for high-volume production.

Cosmetics and Personal Care Products

The mold is also used for producing preforms for cosmetic packaging. Products such as shampoos, lotions, and other personal care items are often packaged in PET bottles. The mold ensures that the preforms are produced with the necessary precision to create visually appealing and functional cosmetic packaging.

英语

英语 法语

法语