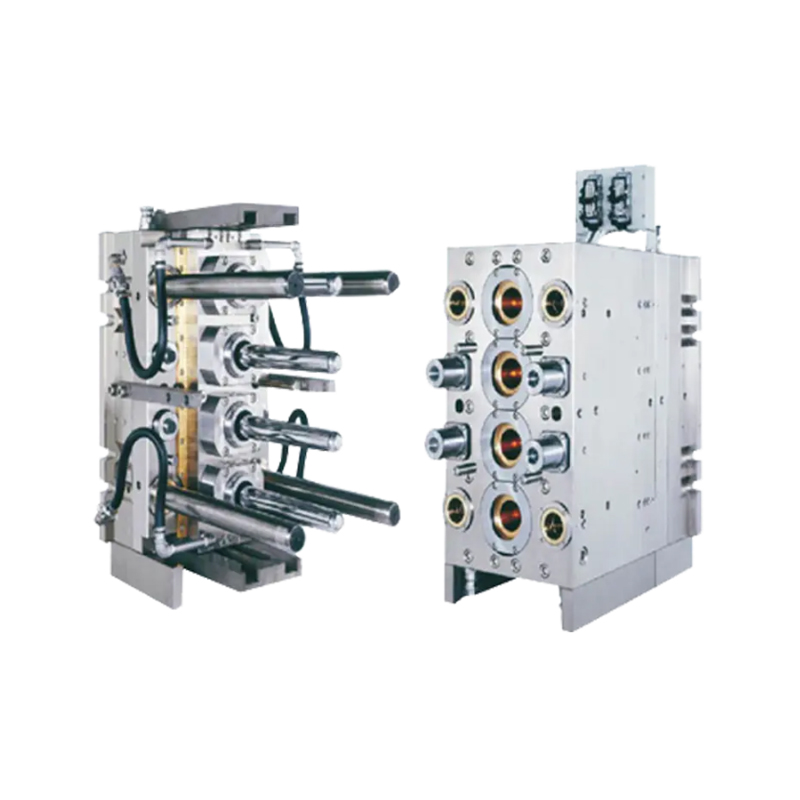

The 4 Cavity 5gallon Preform Mould is an innovative solution designed to enhance the production of wide-mouth jar preforms. This sophisticated mould integrates good technology with practical design features, allowing manufacturers to increase efficiency while producing high-quality preforms suitable for a variety of applications.

Hot Runner System Benefits

The incorporation of a hot runner system within the 4 Cavity 5gallon Preform Mould offers several advantages. This system maintains the plastic material at a consistent temperature, preventing it from cooling prematurely during the injection process. As a result, producers benefit from reduced cycle times and improved material flow, which leads to better overall production consistency. Hot runner technology ensures that the preforms produced are uniform and of high quality, material waste and enhancing cost-effectiveness.

Efficient Cooling Mechanism

Effective cooling is a vital component of the injection moulding process, and the 4 Cavity 5gallon Preform Mould excels in this area as well. The mould incorporates a well-designed cooling system that accelerates heat dissipation from the preforms after injection. Rapid cooling helps maintain the integrity and dimensional accuracy of the preforms while reducing overall cycle times. The cooling system is designed to work simultaneously with the hot runner technology, providing a balanced approach to temperature management.

Versatile Design for Multiple Applications

The 4 Cavity 5gallon Preform Mould is explicitly designed to accommodate a range of wide-mouth jar dimensions. This versatility enables manufacturers to produce various preform sizes suited for different applications, from food containers to cosmetic packaging. This adaptability the need for additional tooling, allowing manufacturers to pivot quickly in response to changes in market demand. The mould's design ensures that manufacturers can produce preforms tailored to specific customer requirements without a lengthy setup process.

Enhanced Production Efficiency

One of the features of the 4 Cavity 5gallon Preform Mould is its ability to produce multiple preforms in a single cycle. With four cavities, this mould can generate four wide-mouth jar preforms simultaneously. This increased output significantly improves manufacturing efficiency, enabling companies to meet production targets more effectively. By optimising cycle times, the 4 Cavity Hot Runner Wide-Mouth Jar Preform Mould can help businesses maintain a steady supply of preforms, ultimately driving profitability.

Precision and Consistency

Maintaining consistent quality is crucial in preform production, and the 4 Cavity 5gallon Preform Mould is engineered to achieve just that. The mould guarantees high precision in dimensions and weight, ensuring that each preform is uniform. This level of consistency is essential for manufacturers who require reliable preforms that fit seamlessly into subsequent filling and capping processes. The ability to produce uniform preforms reduces the likelihood of defects, ensuring that the final products meet intended specifications.

Material Compatibility

The 4 Cavity 5gallon Preform Mould is compatible with various thermoplastic materials, especially PET, which is a standard choice for jar preforms. This compatibility allows manufacturers to choose materials that suit their production needs without being limited by mould specifications. The flexibility in material usage contributes to the overall versatility of the mould, enabling manufacturers to adapt to emerging packaging trends or customer preferences efficiently.

In summary, the 4 Cavity 5gallon Preform Mould is an exemplary solution for manufacturers looking to enhance their efficiency and product quality in the production of wide-mouth jar preforms.

英语

英语 法语

法语