A Cap Mould is a specialized tool used in the manufacturing of caps and closures, primarily for bottles, containers, and various packaging products. These moulds are integral to the production of plastic caps that meet the demands of different industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals.

Advantages of Cap Mould

High Production Efficiency:

One of the main advantages of Cap Moulds is their ability to produce caps at high speeds. These moulds are designed to handle large volumes, enabling manufacturers to meet the demand for caps in industries where high production rates are essential. The efficient production process reduces manufacturing time and costs, helping companies maintain competitive pricing while ensuring product availability.

Consistency and Quality:

Cap Moulds ensure consistent quality across large production runs. With precise moulding, each cap produced has uniform dimensions, smooth surfaces, and accurate threading. This is especially important for industries like pharmaceuticals or beverages, where the integrity and performance of the cap can directly affect the safety and functionality of the product. Moulds with high precision minimize defects, ensuring that each cap meets the required quality standards.

Versatility in Materials:

Cap Moulds are compatible with a wide range of materials, including various plastics such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). This versatility allows manufacturers to produce caps with different characteristics, such as flexibility, strength, and resistance to chemicals. The choice of material can also influence the cost of production, which is an advantage when manufacturers need to balance quality and cost.

Cost-Effectiveness:

Given their high efficiency and the ability to produce large quantities of caps, Cap Moulds are highly cost-effective for mass production. The moulds reduce material waste, improve energy efficiency, and minimize the need for manual labor, all of which contribute to lowering overall production costs. This is particularly beneficial in industries like food and beverage, where large quantities of caps are required daily.

Features of Cap Mould

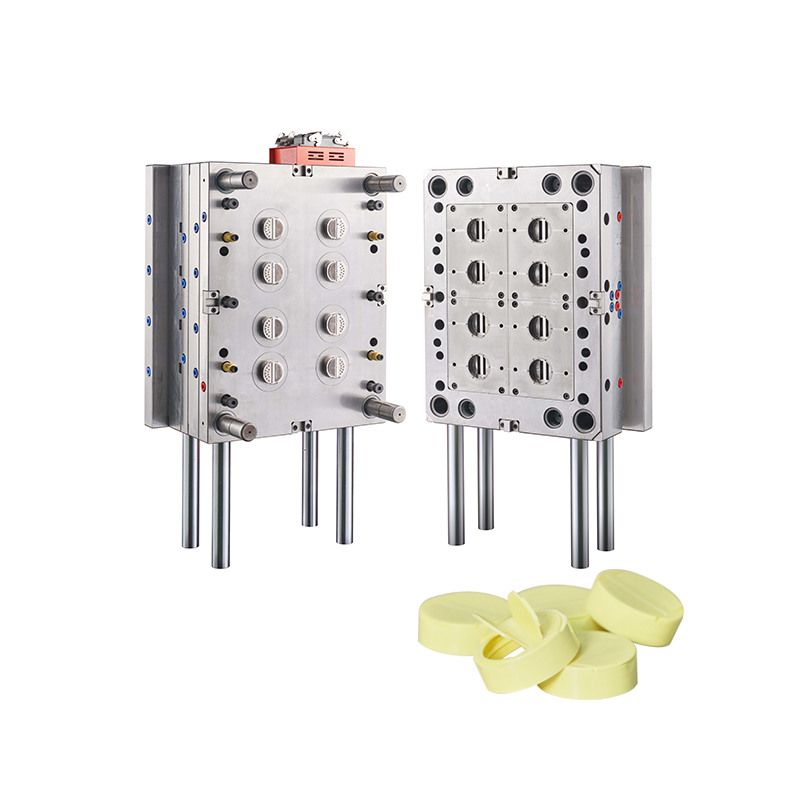

Multi-Cavity Design:

A significant feature of Cap Moulds is the multi-cavity design, which allows the production of multiple caps in a single cycle. Multi-cavity moulds can increase production efficiency by reducing the time required to produce each batch. This feature is essential for meeting the high-volume needs of the packaging industry, where speed and efficiency are critical.

Advanced Cooling Systems:

Cap Moulds are equipped with advanced cooling systems to ensure the rapid and uniform cooling of the moulded caps. Proper cooling reduces cycle times, enhances the quality of the caps by preventing warping or deformation, and ensures better dimensional accuracy. A well-designed cooling system can significantly boost production efficiency and reduce energy consumption.

Precision Threading:

Caps often feature intricate designs such as threads, which are crucial for creating airtight seals. Cap Moulds are designed with precision to create accurate threads that ensure caps fit securely onto containers. The quality of the threading is vital for the proper functionality of the cap, especially in applications that require tamper-evident features or child-resistant designs.

Customization Options:

Many Cap Moulds come with customizable components, such as interchangeable inserts and cavity designs. This flexibility allows manufacturers to produce different types of caps, from simple screw-on caps to more complex designs like flip-tops or dispensing caps. Customization also means that manufacturers can cater to specific customer needs, whether for different container sizes or unique product requirements.

Applications of Cap Mould

Food and Beverage Industry:

Caps are most commonly used in the food and beverage industry, where they seal bottles, jars, and containers. Whether it's bottled water, soft drinks, or sauces, caps ensure the freshness, safety, and quality of the contents. The demand for high-quality, reliable caps is constant, and Cap Moulds play a crucial role in ensuring that these products meet safety standards and consumer expectations.

Pharmaceutical Industry:

In the pharmaceutical sector, the importance of reliable and secure caps cannot be overstated. Caps must meet stringent regulatory standards to ensure that they protect the contents from contamination, preserve the integrity of the medication, and provide tamper-proof features. Medical and pharmaceutical companies rely on Cap Moulds to create caps that meet these exacting requirements while maintaining product safety.

Cosmetics and Personal Care:

Cosmetics and personal care products such as shampoos, lotions, and perfumes also rely on caps for packaging. These caps often require aesthetic appeal along with functionality, as well as features like easy dispensing, airtight seals, or tamper-resistant mechanisms. Cap Moulds for the cosmetic industry must balance both design and functionality, ensuring that the caps are visually appealing while also delivering a secure, high-performance seal.

Chemical Industry:

The chemical industry uses caps for containers holding cleaning agents, solvents, paints, and other chemicals. In this case, the caps must be resistant to chemical exposure and capable of withstanding the pressures of heavy-duty usage. Cap Moulds in the chemical industry are designed to meet these tough requirements by using materials that offer superior chemical resistance and durability.

Packaging for Consumer Goods:

Cap Moulds are widely used in the production of packaging for a variety of consumer goods, including household products, oils, and detergents. These caps are often designed for ease of use, such as screw caps, flip-top lids, or snap-on closures, ensuring that consumers can easily open and close containers without spills or leaks.

Cap Moulds are indispensable in the manufacturing of high-quality, efficient, and reliable caps used across a variety of industries. Their advantages, including high production efficiency, material versatility, and cost-effectiveness, make them crucial for meeting the demands of industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. With features like multi-cavity designs, advanced cooling systems, and precise threading, Cap Moulds ensure the production of caps that are consistent in quality and functional in use. As industries continue to evolve, the role of Cap Moulds in providing secure, reliable packaging solutions will remain integral to the manufacturing process.

英语

英语 法语

法语