No.148 Yongda Road, Jiangkou Street, Huangyan, Taizhou, Zhejiang, China.

As global industries continue to scale, the need for durable, large-capacity packaging solutions has grown steadily. From water bottling plants to industrial chemical suppliers, bulk packaging is no longer a niche market—it's a critical part of operational logistics. At the forefront of this demand stands a highly specialized piece of equipment: the 4 Cavity 5-Gallon Preform Mold. Offering a balance of precision, performance, and scalability, this mold is quietly transforming how manufacturers approach large-volume PET container production.

Driving Efficiency in Bulk Container Production

Traditionally, producing 5-gallon PET containers was a slow, resource-heavy process, often plagued by long cycle times and high per-unit costs. The introduction of the 4 cavity configuration has changed that landscape significantly. By enabling the simultaneous production of four heavy-duty preforms, this mold substantially reduces cycle time while maintaining high product consistency.

For manufacturers in the water delivery, home brewing, or chemical distribution sectors, this translates to faster output, reduced lead times, and more reliable supply chains. In highly competitive markets where meeting large-volume orders on time can make or break contracts, the mold becomes a valuable asset.

Engineered for Strength and Precision

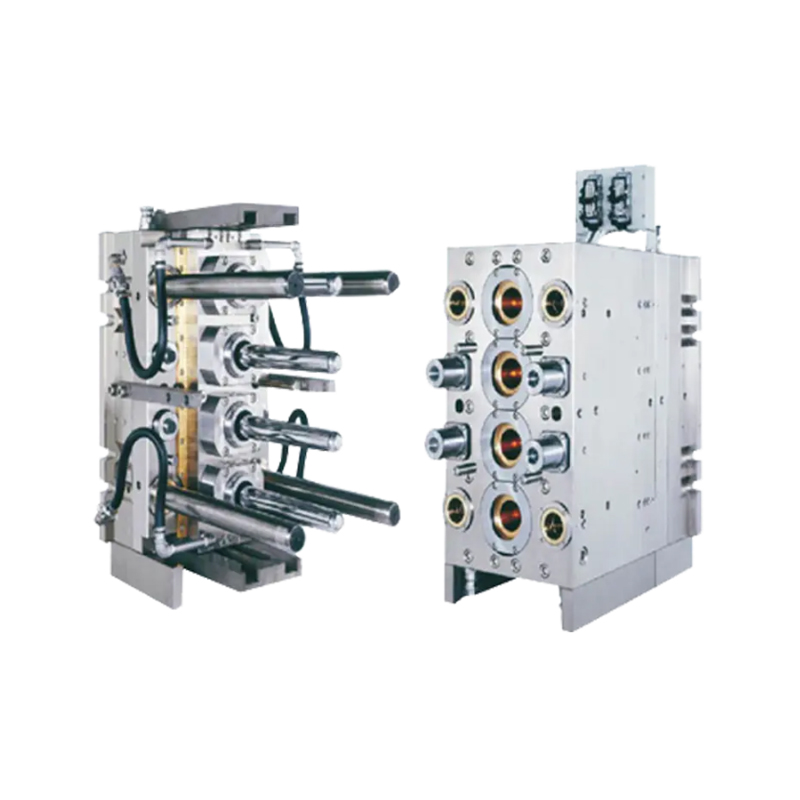

A key challenge in manufacturing preforms for 5-gallon containers lies in ensuring that each preform can withstand both the mechanical stresses of blow molding and the physical demands of end use. The 4 Cavity 5-Gallon Preform Mold addresses this with meticulously machined cavities that maintain precise wall thickness, neck finish, and material distribution.

This precision ensures that the final containers are not only structurally sound but also capable of handling extended storage, stacking, and transportation—particularly important for containers used in food and beverage distribution or industrial applications such as solvents and oils.

Durability Designed for the Long Haul

Manufactured from premium-grade hardened steel or corrosion-resistant stainless alloys, the mold is built to withstand the rigorous conditions of high-pressure injection molding. It is further supported by advanced thermal control systems and hot runner technology, which prevent material degradation and ensure uniform resin flow across all cavities.

This engineering focus ensures that the mold maintains dimensional accuracy even after thousands of cycles, minimizing the frequency of maintenance or cavity reconditioning. For manufacturers operating 24/7 production lines, this long-term durability is crucial to sustaining productivity without costly interruptions.

Adaptable for Multiple Resin Grades

While PET molds are optimized for standard bottle-grade resins, the 4 Cavity 5-Gallon Preform Mold offers material flexibility that supports high-viscosity or specialty-grade PET resins. This adaptability makes it suitable for applications beyond water bottling, such as agricultural chemical storage, household cleaners, or bulk food ingredients.

Its versatility empowers manufacturers to serve multiple market segments with a single mold investment, enhancing ROI and extending product portfolio options without the need for separate tooling.

Boosting Sustainability in Large-Scale Packaging

In an age where environmental responsibility is becoming integral to brand identity, even industrial packaging must evolve. The mold’s precision and controlled resin flow help minimize material waste and scrap, reducing raw material consumption over time. Moreover, the resulting containers are fully recyclable and compatible with post-consumer recycled PET (rPET) content—a key driver for companies seeking eco-friendly packaging alternatives.

By facilitating efficient, low-waste manufacturing of recyclable products, the mold supports broader sustainability initiatives and regulatory compliance in industries transitioning to greener supply chains.

Simplified Integration and Operational Ease

Despite its heavy-duty function, the 4 Cavity 5-Gallon Preform Mold is designed for seamless integration with standard injection molding machines, both legacy and new-generation platforms. Its user-friendly design simplifies installation, mold changes, and daily operation, making it easier for operators to maintain consistent output without extensive retraining.

Additionally, the hot runner system reduces the need for sprue trimming and post-processing, saving valuable time and labor costs on the production floor.

英语

英语 法语

法语