No.148 Yongda Road, Jiangkou Street, Huangyan, Taizhou, Zhejiang, China.

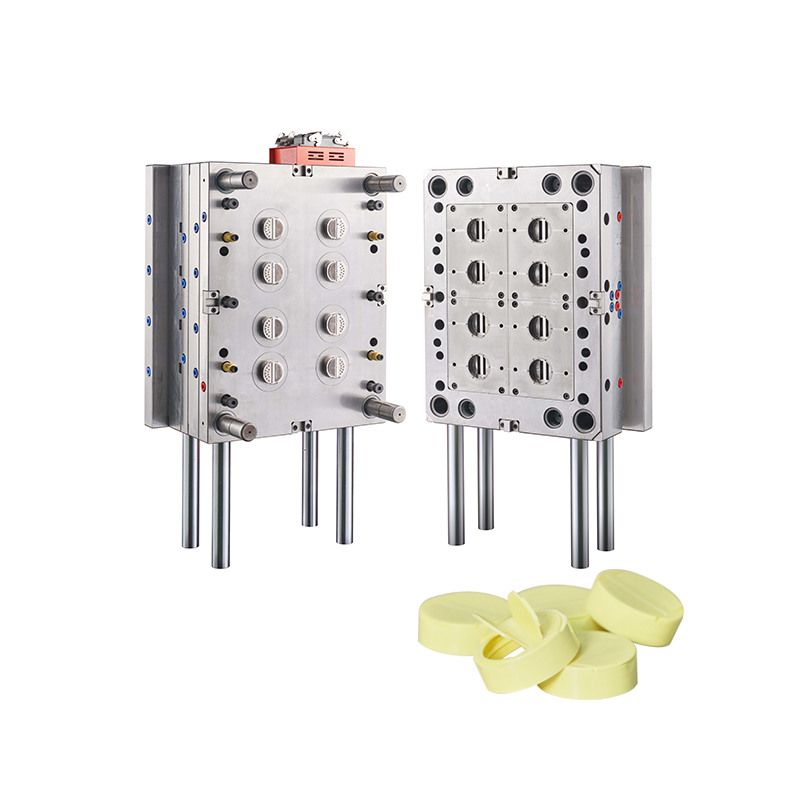

In today’s fast-paced consumer environment, convenience and functionality are more important than ever. Flip caps have emerged as a popular closure solution across a wide range of industries—from beverages and personal care products to household cleaners and pharmaceuticals. Behind the scenes of this packaging innovation lies a critical component: the Flip Cap Mold.

As manufacturers look to meet growing consumer demand for user-friendly packaging, flip cap molds play a pivotal role in delivering precise, reliable, and cost-effective closures that enhance product usability and brand appeal.

Precision Engineering for Consistent Performance

One of the defining features of modern flip cap molds is their meticulous precision engineering. Each cavity within the mold is designed to produce flip caps with uniform dimensions and smooth, functional hinges. This exacting attention to detail ensures that every cap fits perfectly on its corresponding container, providing a secure seal while allowing for easy opening and reclosing.

The precision of these molds minimizes the risk of leaks or malfunctions, which is especially critical for products containing liquids, gels, or powders that require airtight protection. Furthermore, consistent cap geometry facilitates compatibility with automated filling and capping lines, supporting high-volume production without sacrificing quality.

Material Quality Ensures Longevity

Durability is a hallmark of the flip cap molds. These molds are constructed from high-grade tool steels and corrosion-resistant alloys, materials chosen specifically for their ability to withstand the stresses of repeated injection molding cycles. This robust construction not only ensures the longevity of the mold but also maintains dimensional stability over thousands of production runs.

Advanced surface treatments and coatings enhance resistance to wear and polymer adhesion, allowing the mold to deliver smooth, defect-free parts with minimal maintenance. For manufacturers, this translates to lower downtime, reduced maintenance costs, and more consistent output.

Supporting Innovation in Packaging Design

Flip caps have evolved beyond basic closures to become a critical element of product design and branding. Modern flip cap molds enable the production of caps with various features such as tamper-evident seals, child-resistant locking mechanisms, and ergonomic shapes that improve grip and usability.

This flexibility in mold design supports brands seeking to differentiate their products on crowded shelves. By integrating unique shapes, colors, and textures, manufacturers can create packaging that not only protects the product but also enhances consumer experience and loyalty.

Efficiency Gains and Cost Savings

Flip cap molds contribute significantly to manufacturing efficiency. By enabling the production of multiple caps in each molding cycle, these molds increase output while optimizing material usage and energy consumption. High-precision gating and hot runner systems ensure even resin flow, reducing waste and improving cycle times.

Additionally, the uniformity of parts produced helps streamline quality control processes, minimizing rejects and rework. The result is a cost-effective molding solution that supports lean manufacturing principles and sustainable production goals.

Broad Industry Applications

Flip caps molded with precision tools find applications across diverse industries. In the personal care sector, they provide convenient access to lotions, shampoos, and hand sanitizers. For the food and beverage industry, flip caps help preserve freshness and enable easy pouring of sauces, condiments, and beverages.

The pharmaceutical and healthcare industries also rely on flip caps for secure yet accessible medication packaging, while household products like cleaners and detergents benefit from their ease of use and spill prevention.

This versatility underscores the importance of reliable flip cap molds in meeting the varied demands of modern packaging.

Future Trends: Sustainability and Smart Packaging

As the packaging industry moves toward greater sustainability, flip cap molds are adapting to accommodate eco-friendly materials, including bio-based plastics and recycled resins. Mold designs are evolving to reduce material thickness without sacrificing strength, helping manufacturers lower their environmental footprint.

Moreover, the rise of smart packaging—which integrates sensors, QR codes, and tamper indicators—is driving innovation in flip cap mold technology. Manufacturers are exploring ways to incorporate these features into caps without compromising mold cycle times or product integrity.

英语

英语 法语

法语