No.148 Yongda Road, Jiangkou Street, Huangyan, Taizhou, Zhejiang, China.

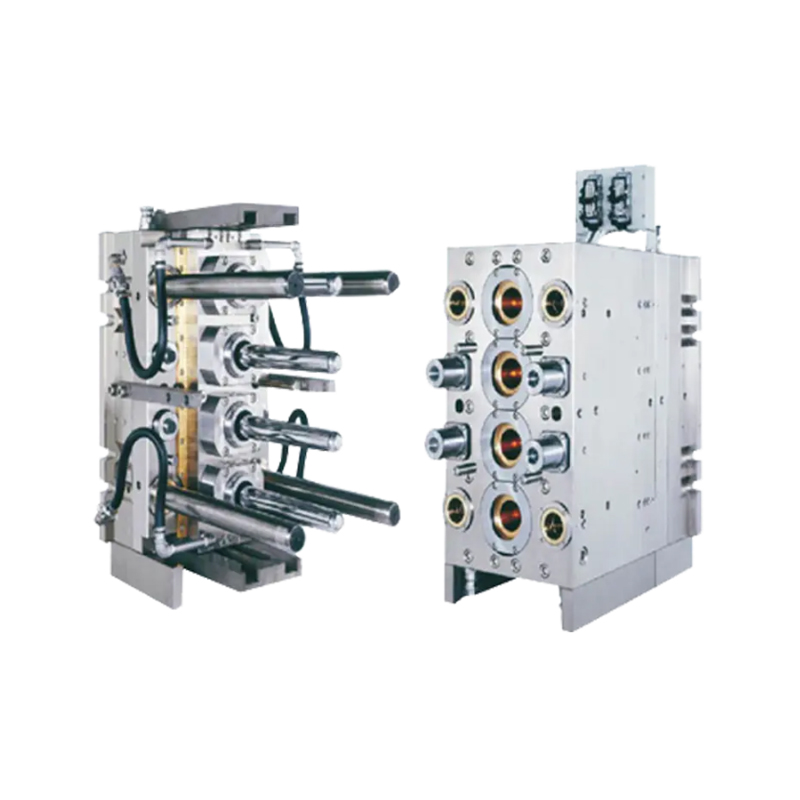

As global demand rises for bulk liquid packaging—especially in water, beverage, and industrial fluid sectors—the need for efficient, large-volume container production has never been more critical. the charge in this specialized field is the 4-Cavity 5-Gallon Preform Mold, a high-performance tooling solution tailored to produce durable preforms for five-gallon PET containers.

This mold combines advanced engineering, robust materials, and process-optimized features to support consistent, high-quality output, making it a top choice for manufacturers focused on large-format container applications.

Meeting the Demands of High-Volume Packaging

The five-gallon PET bottle plays a central role in the global bottled water market, institutional beverage dispensing systems, and chemical packaging. Manufacturers of these containers require preforms with precise material distribution and dimensional stability to withstand the physical stresses of storage, handling, and transportation.

The 4-cavity configuration offers an balance between output and precision. It enables the production of four large preforms per injection cycle, significantly increasing throughput while maintaining a manageable mold size suitable for a wide range of injection machines. This design is ideal for operations scaling up production or maintaining reliable supply for peak demand periods.

High-Tonnage Performance with Dimensional Accuracy

Producing preforms for five-gallon containers involves more complex engineering compared to standard bottle sizes due to their increased volume and structural requirements. The 4-Cavity 5-Gallon Preform Mold is built to handle high shot weights and intense pressures without compromising part consistency.

Each cavity is precision-machined to ensure uniform wall thickness, neck geometry, and overall preform weight. These factors directly affect blow molding success rates and the long-term performance of the finished containers, especially under heavy load or repeated use in returnable bottle systems.

Engineered for Mold Longevity and Minimal Maintenance

To endure the high demands of large-part molding, the mold is constructed from premium-grade stainless and tool steels. These materials offer wear resistance, corrosion protection, and dimensional stability over time.

Hardened inserts, corrosion-resistant cavity components, and surface treatments extend the mold’s service life while reducing the need for frequent maintenance interventions. This reliability makes the mold a strong return on investment, especially for plants running 24/7 production schedules.

Optimized Gate and Flow Design for Uniform Material Distribution

The mold incorporates a balanced hot runner system that ensures even material flow into all four cavities. This prevents common issues such as short shots, sink marks, or weld lines, which are particularly critical to avoid in thick, heavy preforms like those used for five-gallon containers.

A center-fed valve gate system, often employed in such molds, allows for clean, flash-free parting lines and improved preform aesthetics—key for customer-facing applications like bottled water packaging.

Flexibility and Customization to Meet Market Needs

The 4-Cavity 5-Gallon Preform Mold can be customized to produce preforms with varying neck finishes and weights depending on the container’s end use—whether for water, chemicals, or household products. This flexibility supports manufacturers in adapting to evolving market demands or customer specifications without needing an entirely new mold investment.

Quick-change components and modular mold design features also reduce downtime during transitions between product types, supporting lean manufacturing and just-in-time production strategies.

Integration with Modern Injection Molding Lines

The mold is designed to integrate seamlessly with high-tonnage injection molding machines commonly used in large-part manufacturing. It supports robotic part removal, automated vision systems for quality control, and temperature regulation tools that enhance repeatability and process control.

In addition, its compatibility with PET material—both virgin and recycled (rPET)—makes it well-suited for companies looking to expand their sustainability initiatives without sacrificing mechanical performance or visual appeal.

Supporting Global Trends in Water and Industrial Packaging

The surge in demand for clean drinking water, industrial fluids, and bulk packaging solutions—particularly in emerging markets—continues to drive investment in five-gallon PET bottle production. Whether for home dispensers, office water coolers, or institutional settings, the demand for rugged, lightweight containers is only expected to increase.

英语

英语 法语

法语