No.148 Yongda Road, Jiangkou Street, Huangyan, Taizhou, Zhejiang, China.

As consumer preferences evolve and packaging standards grow more stringent, the packaging industry has seen a marked increase in demand for user-friendly and functional closures. One solution gaining traction across personal care, food, pharmaceutical, and household sectors is the Flip Cap Mold—a high-performance mold designed to produce hinged plastic caps with precision, speed, and reliability.

These flip caps, recognized for their convenience and intuitive design, are critical components in packaging formats that prioritize cleanliness, resealability, and consumer experience. With this in mind, manufacturers are turning to advanced flip cap molds to stay competitive in a fast-paced, design-conscious market.

Addressing Market Demands for Functional and Aesthetic Closures

In today’s consumer-driven packaging world, functionality is just as important as appearance. Flip caps offer both. Their ability to open with one hand and reseal tightly makes them ideal for liquid products like shampoos, sauces, sanitizers, and lotions. This increasing demand for flip-top packaging has sparked innovation in mold design to accommodate high-volume production without sacrificing quality.

The generation of flip cap molds does more than just produce parts—it enables brand differentiation through consistent output, smooth finishes, and precise hinge performance.

Precision Engineering for Complex Part Geometry

Unlike basic caps, flip caps incorporate moving components—primarily the hinged lid. Molding such designs requires accuracy to ensure that each cap closes securely, aligns perfectly, and operates with ease over repeated use. Poorly molded hinges or inconsistent closure force can result in leaking, breakage, or product contamination.

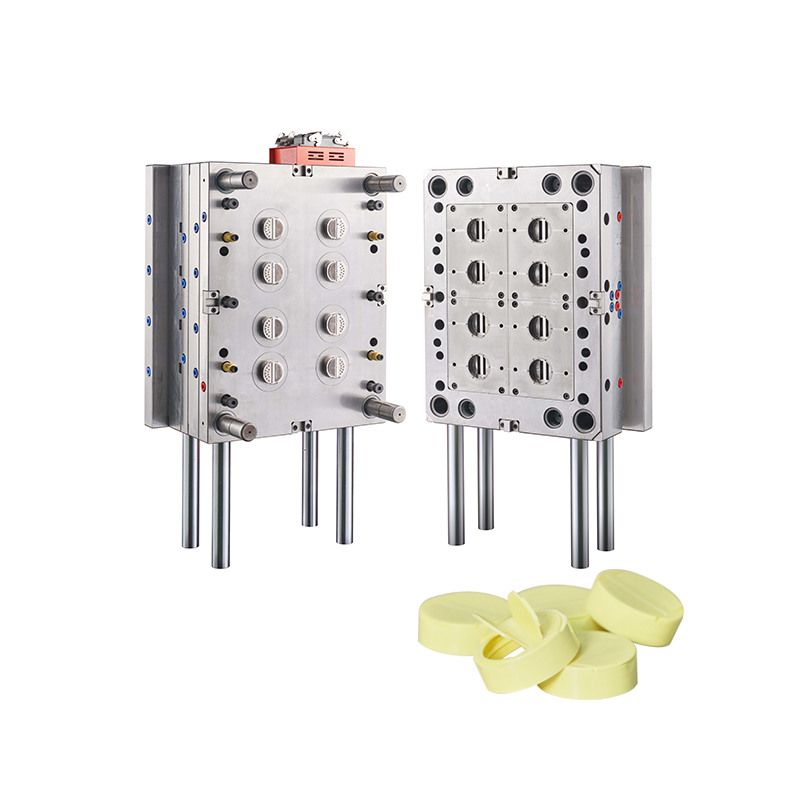

The Flip Cap Mold leverages precision cavity design and advanced tooling techniques to ensure the hinge area is consistently formed across all cavities. Each part meets tight tolerances for the locking mechanism, hinge integrity, and snap-fit function—qualities that are especially critical in pharmaceutical and food applications.

High Cavity Configuration with Uniform Output

Modern flip cap molds are available in high-cavity configurations—ranging from 8 to 32 cavities or more—allowing manufacturers to scale up production while maintaining consistent quality. Cavity balancing is meticulously calibrated to ensure uniform resin flow, avoiding defects like short shots, warping, or incomplete hinges.

This uniformity across cavities minimizes scrap rates and reduces downstream rework, making the mold not only productive but also cost-effective over time.

Advanced Gating and Ejection Systems

The efficiency of the flip cap mold is supported by its integration with hot runner systems and valve gate technology. These features enable precise, direct injection into each cavity, ensuring optimal resin distribution and minimizing material waste. By eliminating cold runners, manufacturers benefit from faster cycle times, reduced energy consumption, and cleaner parting lines.

A specially engineered ejection system ensures gentle and reliable demolding of the delicate cap and hinge structures. This is crucial for preventing damage during high-speed production and ensuring the functional performance of the final product.

Material Compatibility and Sustainability

The flip cap mold is compatible with a range of plastic materials including polypropylene (PP), high-density polyethylene (HDPE), and bio-based polymers. This flexibility allows manufacturers to align their output with both customer demands and environmental objectives.

With sustainability at the forefront of many packaging strategies, the ability to mold recyclable and compostable materials using the same tool adds significant value. Lightweighting options and optimized resin usage further contribute to greener manufacturing processes.

Mold Longevity and Production Reliability

The mold’s construction uses hardened tool steels and wear-resistant coatings, enabling it to withstand the pressures of long-term, high-volume production. Critical areas—such as hinge core inserts and parting lines—are reinforced and precision-machined to retain dimensional accuracy even after millions of cycles.

Additionally, the mold is designed with modular components that simplify repair and replacement. Manufacturers benefit from reduced downtime during maintenance, quick changeover capabilities, and fewer disruptions in the production schedule.

Enhancing Brand Identity and User Experience

In highly competitive retail environments, packaging plays a significant role in brand recognition. A well-made flip cap enhances product value by offering ease of use, tamper evidence, and a sleek visual appeal.

英语

英语 法语

法语